Footwear TRACISCORE

The footwear industry’s data architecture standard for shoe traceability at the product level

- Directs the footwear industry on which materials and components need to be mapped across all supplier tiers.

- Establishes a clear scoring system for the entire industry to unify efforts in complying with EU DPP regulations.

- Provides a comprehensive operations roadmap for traceability programs, including how to prioritize areas tied to regulatory

compliance, in a way that will help clearly communicate what we need suppliers to provide. - Developed by industry leaders and experts to align efforts to ensure industry success.

- Informs policymakers on unique shoe traceabilty challenges, with standards they can adopt.

- Published by FDRA, the footwear industry's association, as the industry's standard.

Tool published September 2024. The tool will update in 2025 complete with all shoe component areas. Companies can begin their work now on Phase 1 areas.

Footwear is more like a Tesla than a T-shirt.

It's why this tool was created.

THE PROBLEM: traceability standards throwing shoes in with apparel

- Shoes have 10x more materials than clothes/'textiles'.

- Shoes have 30+ materials not seen in 'textiles' including steel and foams.

- Shoe supply chains are unique and vast, in part due to the variety of materials that must be used to produce a product that must perform on feet every step.

- Yet, the push for erroneous one-sized fits all "fashion/textile" standards continues from retailers to organizations to governments.

- Wrong assumptions that standards made for clothing can just apply to shoes must end—they cannot succeed.

- Consider this: airplanes and trains are both in the transportation industry—should their standards be the same?

WHAT WORKS: individual right-sized standards for each "fashion" product – hence this tool for footwear specifically.

- There are clear and vital differences between shoes and shirt materials and supply chains.

- Once this is realized, the only way forward is right-sized traceability standards, policy, and programs by each product type.

- One for clothing. One for shoes. One for Handbags. One for accessories.

- Some targets may be shared, but differences must be accounted for and unique scopes must be made.

- Real success requires multiple policy tracks and standards that fit each individual "fashion" product, like shoes. AND different timelines for implementations - recognising that it may take a year or more longer than apperal for footwear traceability compliance.

Features of the Tool

Roadmap to tracing down to raw material creation

- Provides an operational guide stepping through a supply chain, mapping suppliers and materials.

- Identifies gaps to target and critical areas to focus efforts.

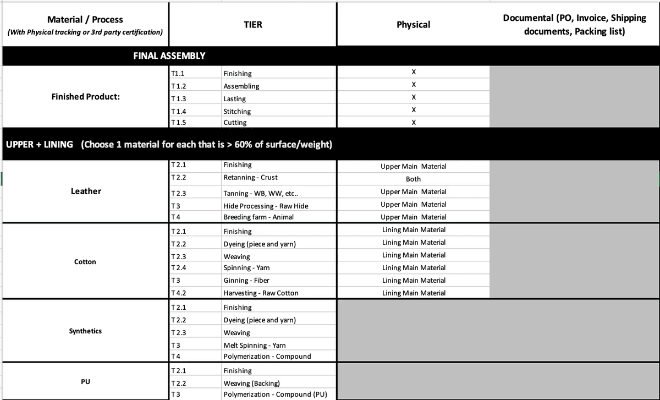

Organized and meticulous data input system by material and shoe area

- Segments shoe into upper, lining, outsole and insole, and inquires their material types.

- Inquires on process: tanning, dyeing, weaving, polymerization, harvesting, etc.

Scoring percents based on traceability tier depth and type of verification

- Assigns scores based on key areas and depth of traceability.

- Greater percents provided to physical vs. documented traceability, and further toward T4.

Deeper Background on TRACISCORE

Why does the footwear industry need this tool?

Who developed this tool?

Why should policymakers study this tool for adoption?

What are the principals of this tool?

What are next steps to finalize this tool?

Shoe Supplier Tiers Defined

Shoe Supplier Tiers Defined:

- TIER 1 SUPPLIERS: take processed materials and components and assemble a final shoe, package and send them to the footwear brand/retailer.

- TIER 2 SUPPLIERS: develop refined raw materials into processed components going into Tier 1 final assembly: like the rubber soles, molded foams, fabric uppers, or insoles that are used to create the finished shoe.

- TIER 3 SUPPLIERS: prepare / refine raw materials for Tier 2: like slaughterhouses/tanneries, chemical processing plants into synthetics/plastics, textile mills/yarn spinners/cotton gins, rubber vulcanizer, pelletized EVA, etc.

- TIER 4 SUPPLIERS: farms, mines, and/or labs that provide raw materials. Examples: farming cotton, farms extracting rubber from trees, cattle farm, metal / mineral mines, or oil extraction company.

© 2026 FDRA